INTRODUCTION TO MTM

Acroname, Inc. has been bringing robotics and automation systems into the hands of engineers for more than 20 years. Our customers include some of the largest corporations and research institutions in the world all the way down to elementary school students. We also advise and supply custom designs to some of the largest consumer electronic manufacturers in the United States and abroad.

With our MTM series, Acroname is enabling manufacturers at all levels to afford and utilize the same test automation as the big players as well as massively reducing capital costs for the big players themselves. Acroname enables companies to reduce the bring-up time of their lines, accelerate ramps to mass production and produce favorable capital-cost reductions. MTM is based on twenty years of experience in microcontroller-based automation and control systems. Hundreds of thousands of our controllers are actively being used by major cellphone and tablet manufacturers currently. The wide range of MTM modules makes it easy to design robust, cost-effective, re-usable, fast-ramping test systems for almost any electronic product.

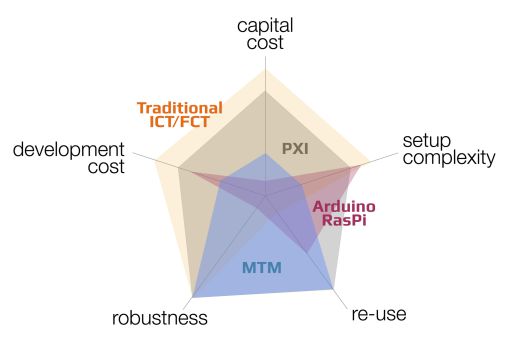

Setting up a manufacturing process is complicated and designing good test systems is paramount in product manufacturing. MTM strikes the perfect balance between capital cost, re-usability, setup complexity and development cost. An MTM based test station provides all the functionality needed to execute a required test plan and nothing more.

ROBUSTNESS

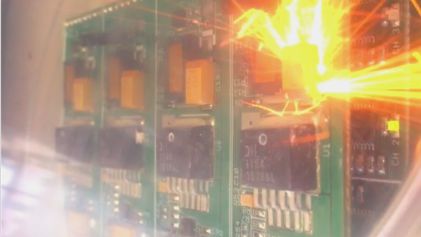

Many manufacturers use large racks of lab equipment in their manufacturing lines. Not only is this equipment expensive, but in most cases it is designed to be operated by a trained engineer. If something goes wrong, the equipment can quickly destroy hundreds of devices under test (DUTs) or even damage itself. In manufacturing environments, there are many things that can go wrong and there usually isn't always someone who can respond to avoid such damage. When damage occurs, replacing the equipment is expensive, but stopping the manufacturing line is catastrophic. MTM is designed to be robust regarding issues which occur in high volume manufacturing. Each module has been created to survive faults ranging from operator error, station misconfiguration or setup error, bad or incorrect DUT, etc. When using test stations built on Acroname's MTM, you can rest assured that your test line will stay running even while you're sleeping.

CAPITAL EXPENSE

There's a difference between cheap and inexpensive; MTM is inexpensive, but certainly not cheap. Each module is designed to replicate the performance of bench equipment, with only the features relevant to manufacturing testing. Switching to MTM based testing can produce enormous cost savings. One manufacturer reduced their functional circuit test (FCT) station capital-cost by more than 50% simply by replacing lab bench power supplies.

RE-USE

In many cases, because they are so inexpensive, our customers have difficulty classifying MTM modules as capital expenditures. The modular and extensible approach embodied in MTM allows for continuous re-use across test stations, product revisions, and products lines. The MTM modules are possibly even more reusable than bench-type equipment, since feature expansions can be done by adding new modules instead of replacing equipment. When high demand drives upgrading your test line from "1-up" testing to "multi-up", simply drop in more MTM modules and scale your output. MTM modules are designed to outlive the products they ship.

DEVELOPMENT TIME AND COST

Bringing a product to market is complicated and full of risks. The MTM system allows your test line to scale with your manufacturing volume, but also with your test requirements. During early prototype builds, hardware engineers usually want to extensively test and characterize the product. Many of the tests are removed or move to a sampling-line once the design is finalized and mass production begins. With MTM modules, the engineering characterization stations utilize more advanced modules which are simply removed from the mass production test stations. The same fixtures, test stations and test software can be used for the deep engineering characterization line and mass production test lines.

Additionally, the fixtures used for prototype builds can be designed to handle multiple DUTs, even if prototype volumes don't necessitate it. With this, the manufacturing process can be proved out at the same time as the design. When it comes time to ramp production volumes, simply drop in more MTM modules to the fixtures to scale your line to highly efficient multi-DUT testing.

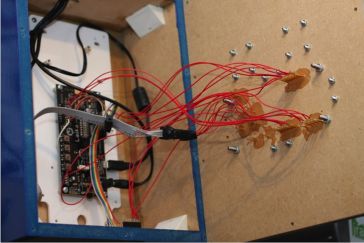

STATION COMPLEXITY

FCT and ICT stations are complex. Large test spectrums and dense product designs have lead to test stations with stacks of lab bench type test equipment heaped into racks. Long wires and ribbon cables connect these racks to test fixtures where more wiring connects signal and power lines to test probes and finally DUTs. As any test engineer, line leader or operations manager knows, it takes a long time and lots of debugging to get these stations working. All this redundancy also reduces test accuracy, increases station-to-station test variance, and thus reduces test line efficiency through higher retest rates.

The MTM system allows these bulky racks to be compressed into a few modular PCBs that fit neatly inside the test fixture. A low cost interface PCB, which usually doubles as the test point mounting PCB, reduces the wiring complexity to near nothing. Station bring-up no longer requires a team of technicians with wire-wrap tools and multimeters. The MTM modules are simply slotted into the interface PCB and powered on. The setup of an MTM based test station is so easy that changing a line to test a different product can be done in hours instead of weeks. With MTM based test stations, CMs and OEMs realize higher line utilization, less bring-up and debugging time, no wiring mistakes or broken wires and improved test line throughput.

BRAINSTEM PLATFORM

All MTM modules are built on top of the robust and extensible BrainStem platform. This platform provides a simple object-like API for writing host-based applications and embedded applications which run on the modules. The BrainStem platform operates on a multithreaded soft real-time OS layer and embedded virtual runtime machine which allows for the quick creation of complex DUT interactions without the need for host-PC communications. The BrainStem platform is completely link-agnostic, meaning the system can run with or without a host-PC. If a host-PC is used, the same application can connect to the test station with USB or Ethernet, allowing for massive scaling of test lines without needing to setup massive numbers of PCs. The BrainStem APIs are completely cross-platform (Mac, Linux and Windows) with no changes to code.

MAKE MTM WORK FOR YOU

Acroname’s years of experience in high-volume manufacturing has lead to the development of the MTM system. Let this experience turn your manufacturing test line into one that rivals the big players. Realize improved test coverage, faster ramps, less station debugging and spend more time shipping your amazing products.

Add New Comment