Mobile devices are designed to survive while crammed into pockets day-in and day-out; they can even survive being handled by toddlers and teenagers. Yet placing thousands of phones or tablets onto server racks can create a more challenging environment for these devices to survive long-term. The continuous battery charging, high processor usage, and high temperatures present in the racks of test labs present unique challenges to device longevity, because the devices were not designed for these applications. The most prominent failure mechanism under these conditions is battery swelling. If left unchecked, these devices may undergo RUD: rapid unplanned disassembly. Obviously, such an event can be catastrophically expensive and even dangerous.

We put together a whitepaper breaking down the risks, causes, and most common mitigations for battery swelling.

Why Batteries Swell

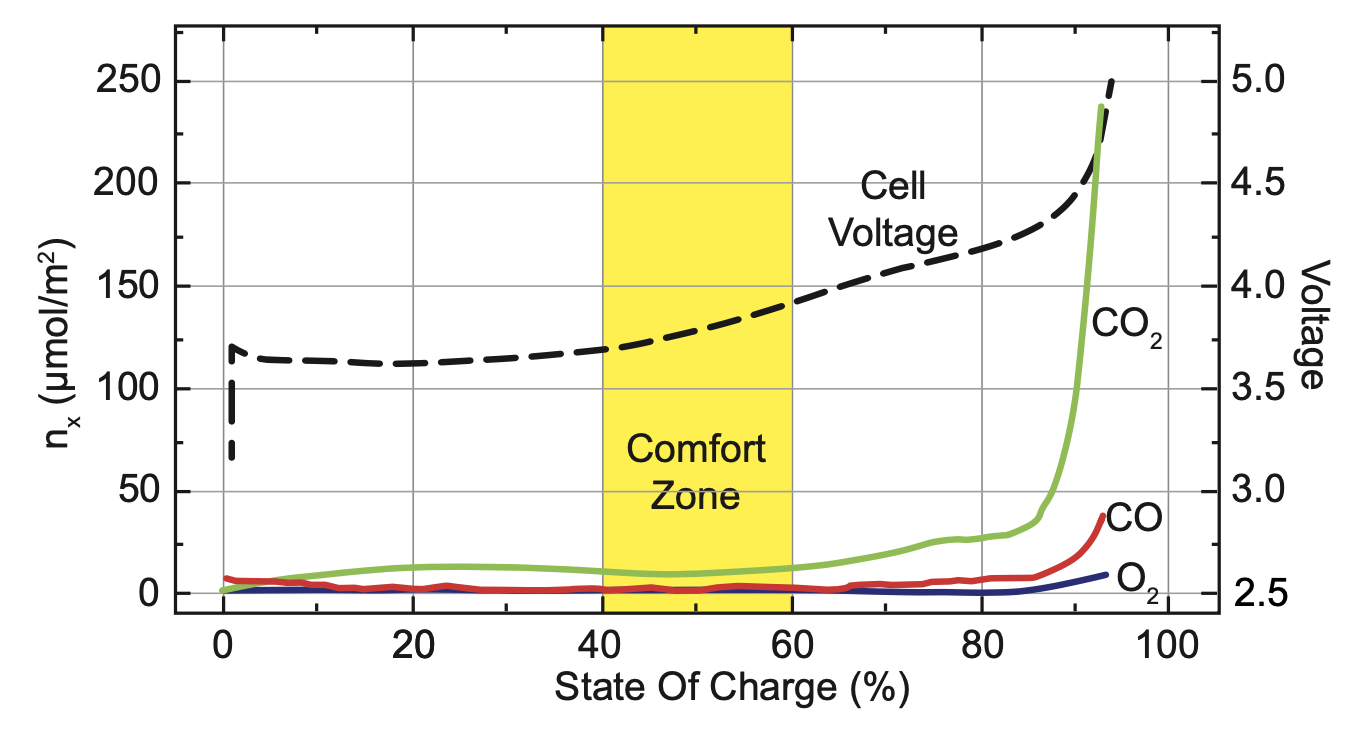

In order to mitigate battery-swell in device labs, it is useful to understand the underlying causes of the issue. It is obvious that battery-swelling is caused by generation of a gas within the cell. Forced overcharging can cause gas generation, but almost all modern devices have protection systems to prevent overcharging. A deeper understanding of the root causes of this gas generation enables engineers to design and implement systems that reduce battery-swell frequency in device-lab environments.

Overview Of Our Device Management System For Batteries

Mitigating battery swell in device labs is important to ensure the longevity and safety of lithium battery-powered devices used for software testing. The dense arrays of devices in these labs are typically connected continuously for long periods of time, which can lead to battery swelling, device failure, and even fires. Understanding the underlying causes of battery swelling is important for designing and implementing systems that extend device service life. Battery swelling is inevitable, but the rate is dependent on temperature and battery state of charge. Acroname’s programable USB hubs can measure and control battery charging currents to keep battery state of charge in specific battery “comfort zones”. In conjunction with sufficient cooling and ventilation, proper control of charge levels can significantly increase device lifespans. Device lab managers implementing these solutions can ensure the safe and efficient operation of their fleets of devices.

How Acroname Programmable USB Hubs Play a Crucial Role in Reducing Battery Swelling

The Acroname USBHub3c programmable USB hub can directly control and monitor charge current at each port. By communicating via PD, the USBHub3c and MD can adjust charge current all the way to 0A while maintaining their USB data connection. In the device lab application, the lowest sufficient charge current can be selected manually or automatically to keep the device within the desired range of charge. Figure 7 shows an updated charging flowchart without disconnections using three current levels.

Comments

Amazing!

We struggle to keep old devices running and available; we've gone as far as "rationing" access to them for testing. You've shown that we can not only ration access, but we can essentially plan for the mobile device lifespan. Powerful!

Add new comment