I. INTRODUCTION

This case study demonstrates how a device lab resolved its USB issues using Acroname’s industrial USB hubs, making the lab more robust and ready to accommodate future expansion.

Hardware device labs need reliable equipment. Often, these labs develop in an ad hoc manner, adding equipment as needed. The reliability and power capabilities of the USB hub itself are often overlooked.

While consumer-grade equipment can be sufficient for simple bench-top testing, it may not scale to more devices, extended uptime, and higher power demands. Unfortunately, USB hardware often fails in intermittent, hard-to-debug ways that can take up valuable engineering time. Devices under test can end up in unknown states, requiring rebooting and plug-unplug cycles.

II. THE PROBLEM: CONTINUOUS INTEGRATION, INTERMITTENT FAILURES

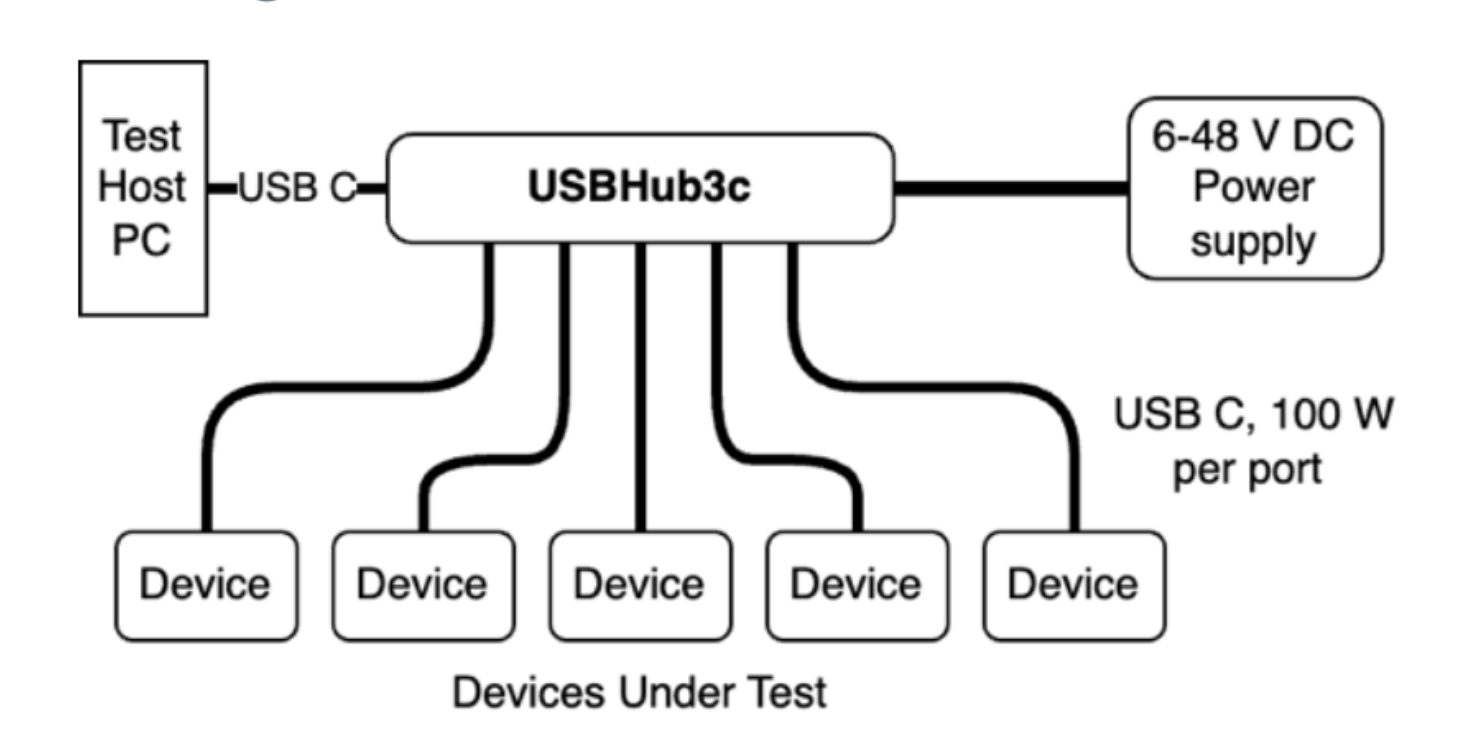

An R&D team was building a small lab to test an array of prototype USB-based devices as part of a continuous integration (CI) test system. A host PC would automate firmware uploading and testing, connecting to devices through a USB hub. This lab would need be replicated in multiple locations, potentially globally, with identical equipment at each location.

Engineers initially purchased a few consumer-grade USB hubs from Amazon. While the system appeared to work at first, intermittent connection failures started appearing during extended tests. Sometimes, individual devices would reset or lose connection; other times, multiple devices or the entire hub would drop the connection, interrupting important test batches.

After two weeks of troubleshooting, the team determined that the consumer-grade hub could not provide sufficient power for the devices when booting or under other high-power modes. This power over-draw caused the hubs to brown-out, causing the observed device disconnects.

III. THE INDUSTRIAL SOLUTION: USBHUB3C

Acroname’s USBHub3c offersindustrial-grade hardware with set-and-forget reliability, even under heavy testing. Uniquely, it can provide up to 100 W of power per port, leaving plenty of headroom for devices in high-power states.

When the lab replaced their hubs with USBHub3c, the intermittent failures disappeared, and the team was able to get back to testing.

Figure 1: USBHub3C

Figure 2: Hardware device testing with USBHub3c

IV. ADDITIONAL BENEFITS

Cable Testing

The customer also used USBHub3c to uncover another weakness in their lab setup: cables. By using USBHub3c to read the USB-C cable e-mark, they discovered that although they had ordered cables of the same brand and model number, the underlying cable manufacturer and quality varied substantially.

Industrial Mounting Features

USBHub3c supports screw-lock cables and DIN rail mounting hardware to ensure that the customer’s test setup stays put.

Full-featured API and GUI

USBHub3c can be controlled via API or GUI, offering robust telemetry and control of each port’s power and data. The customer used the API to simulate plugging and unplugging of devices.

V. CONCLUSION

As device labs scale up, the penalty for unreliable hardware increases. With industrial quality and the highest power per port, Acroname hubs ensure that tests can keep running in the most demanding circumstances.

Add new comment