I. Introduction to USB Power Delivery (PD) Sink Testing

USB Power Delivery (USB PD) is a convenient way to power a variety of devices. Since a USB PD sink device could be connected to any PD source, sinks need to work safely and correctly with any source they might encounter.

The USBHub3c by Acroname is an industrial USB-C hub that can emulate any PD source up to 100 W per port to test PD sink capabilities.

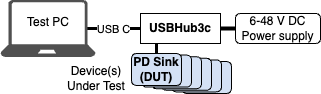

Figure 1: Sink test block diagram

Testing can be interactive using the HubTool application or automated via the BrainStem API, making it relevant to many production and development environments including:

Production test: Functional circuit and final assembly testing.

Functional design validation: Interactive and automated bench testing and development.

Continuous Integration (CI) labs: PD sink testing across software and firmware iterations.

II. Add-On Features for PD Sink Testing

Production and Validation features:

- PD-Builder: Allows customizing local Power Data Objects (PDOs) to emulate various PD source capabilities. Includes Power Rule Editor.

- Quick Charge: Adds legacy Qualcomm Quick Charge (QC2, QC3) support on ports 0-5.

Additional Validation Features:

- Vbus Validation Feature: Lets USBHub3c override Vbus voltage set points and current limits to test a sink’s response to incorrect voltages.

- PD Logger Feature: Logs PD communications across all USBHub3c ports.

Upgraded power supply

- 280W 24VDC Desktop AC/DC Power Adapter: Provides headroom for high-power applications.

III. PD sink emulation

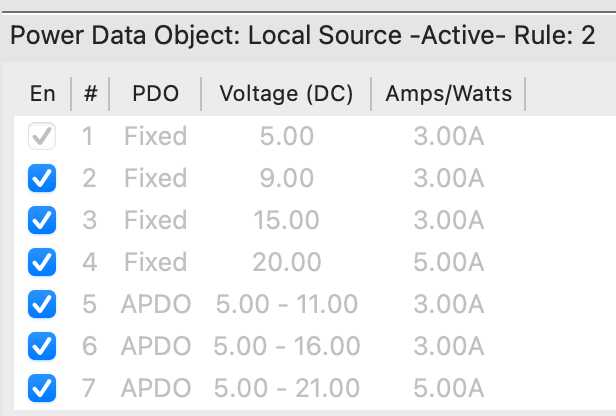

Out of the box, USBHub3c advertises a set of PDOs typical of a modern 100 W PD source, presenting fixed voltages at 5, 9, 15, and 20 V, as well as three Augmented PDO (APDO) variable voltage ranges. These are visible in the Local Source tab (Figure 2).

Figure 2: Default USBHub3c PDOs

The active power rule number is indicated at the top of the tab.

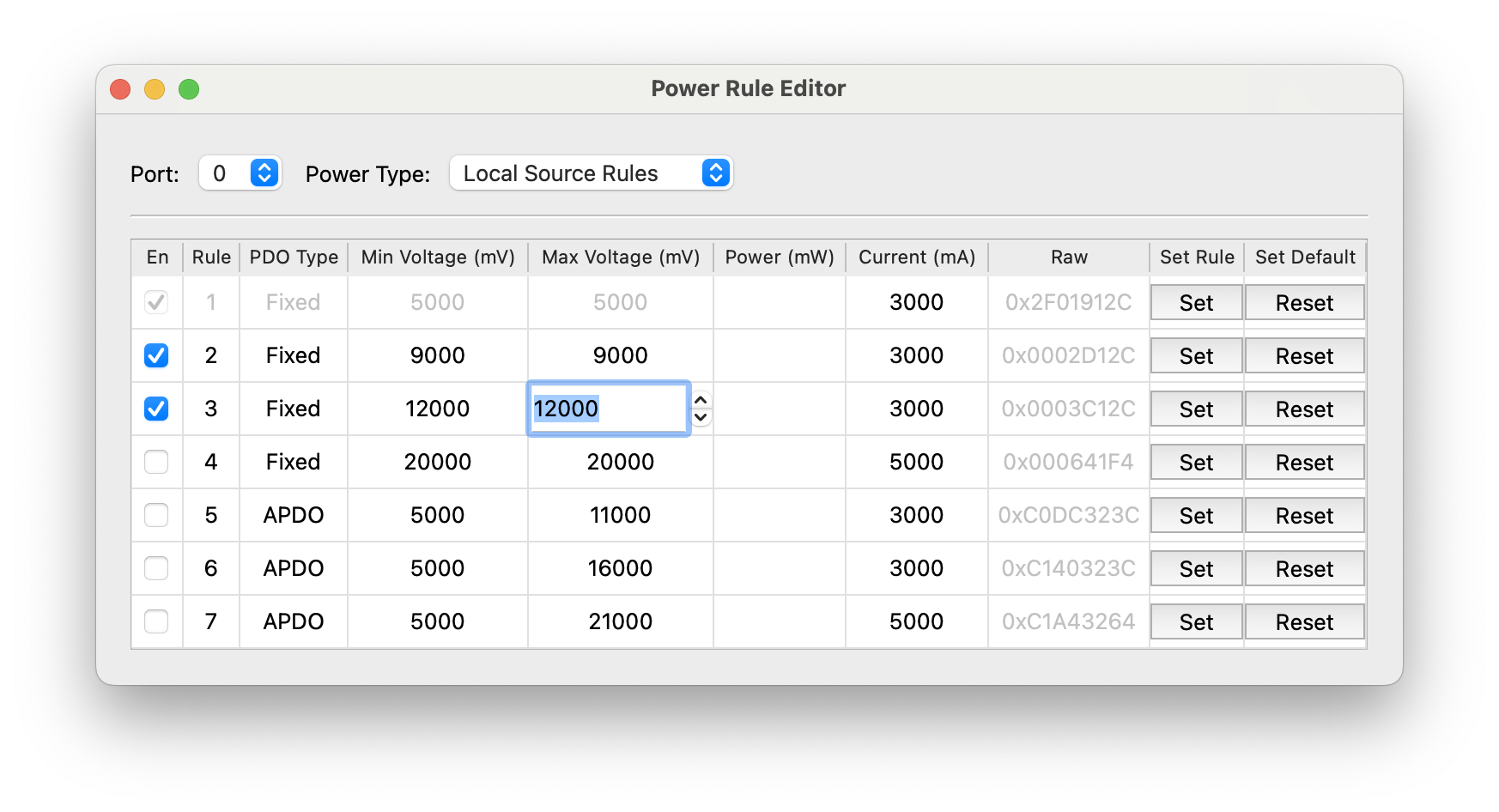

Figure 3: Customize source PDOs

Using the Power Rule Editor (Fig. 3), users can customize the source PDO list to emulate specific PD sources. For example, to simulate an older PD source that supports only 5, 9, and 12 V fixed voltage PDOs, adjust rule 3 to set both the min and max voltage to 12000 mV and disable rules 4-7 (Figure 3).

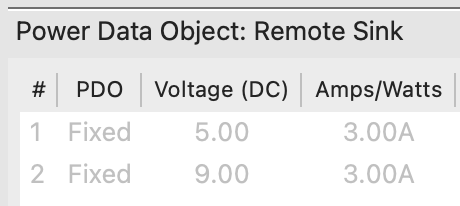

Figure 4: Sink PDOs

In the Remote Sink tab (Figure 4), the sink’s supported PDOs are displayed. You can verify whether the sink correctly chooses the best PDO for its static and dynamic power requirements, such as when transitioning from idle to active modes. If the preferred PDO is unavailable, you can observe the sink's ability to negotiate and choose the next-best available power option.

To enable automated testing, the BrainStem API Power Delivery Class provides functions to directly control power rules and settings.

IV. PD negotiation and message handling

USBHub3c can log and monitor all Power Delivery communication across all ports, with the ability to:

- Decode PD messages.

- Filter USB-PD traffic by message type.

- Display PD message direction.

- Send arbitrary Vendor Defined Messages (VDMs) to control specialized device functions

- Export PD message logs to CSV for post-test analysis

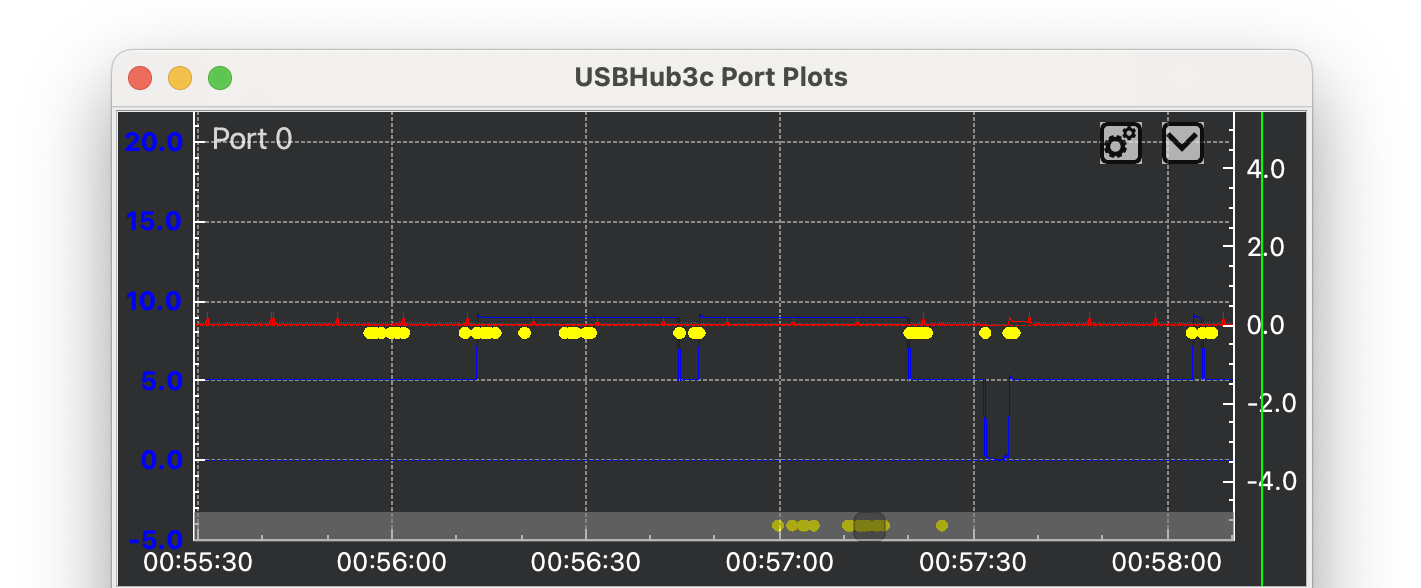

Figure 5: PD messages in plot

Logged PD messages are highlighted in the voltage and current plot window for a clear correlation between PD messages and power delivered.

V. Overvoltage tolerance and Shutdown behavior

PD sink devices may encounter sources that provide unexpected voltages. The Vbus Validation feature offers direct control of Vbus independent from the negotiated voltage, allowing users to test sink devices' voltage variation tolerance, and to observe sink shutdown behavior and power renegotiation.

VI. Reliable USB PD Testing with USBHub3c

Acroname’s USBHub3c offers a flexible solution for PD sink testing across production, design validation and continuous integration environments. Ensure that your sink devices operate safely and reliably no matter what source is connected.

Add New Comment