Hokuyo Factory Reset Procedure

A few customers have mentioned that, when trying to reset the Hokuyo UST-10LX or UST-20LX sensors to the factory default IP address, the reset procedure found in the product specification may not reset the IP address properly.

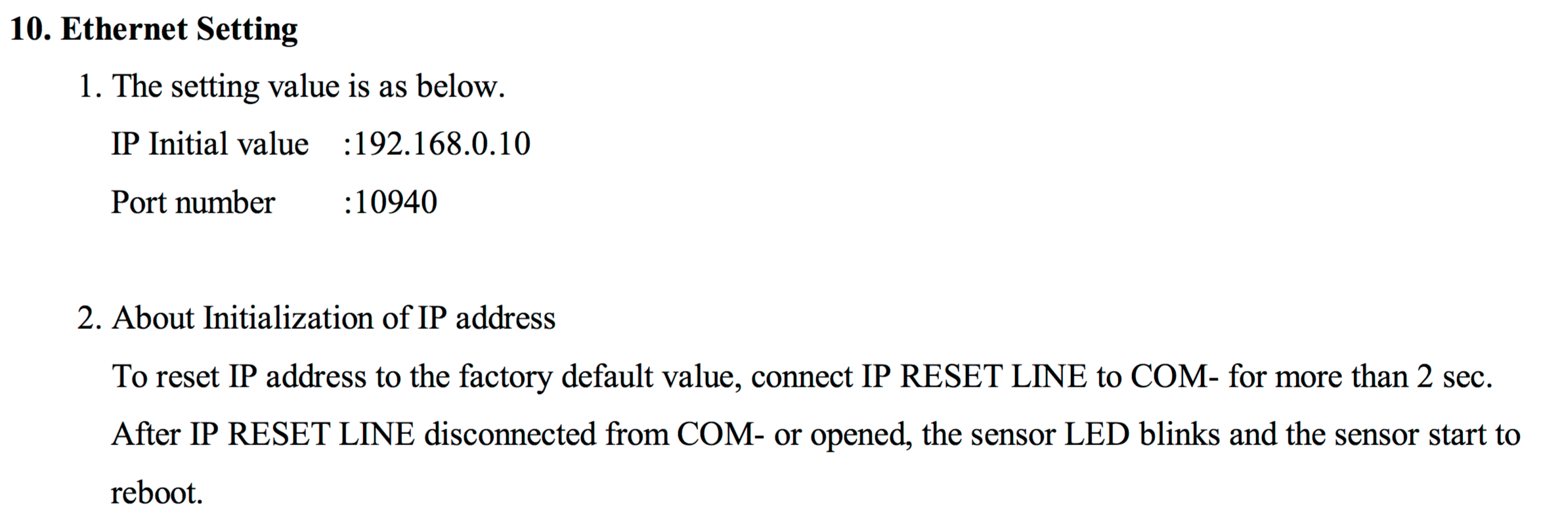

Per the UST-20LX Product Specification 2014.6.12, the process to reset the sensor's IP address to factory default value is shown in Section 10 as follows:

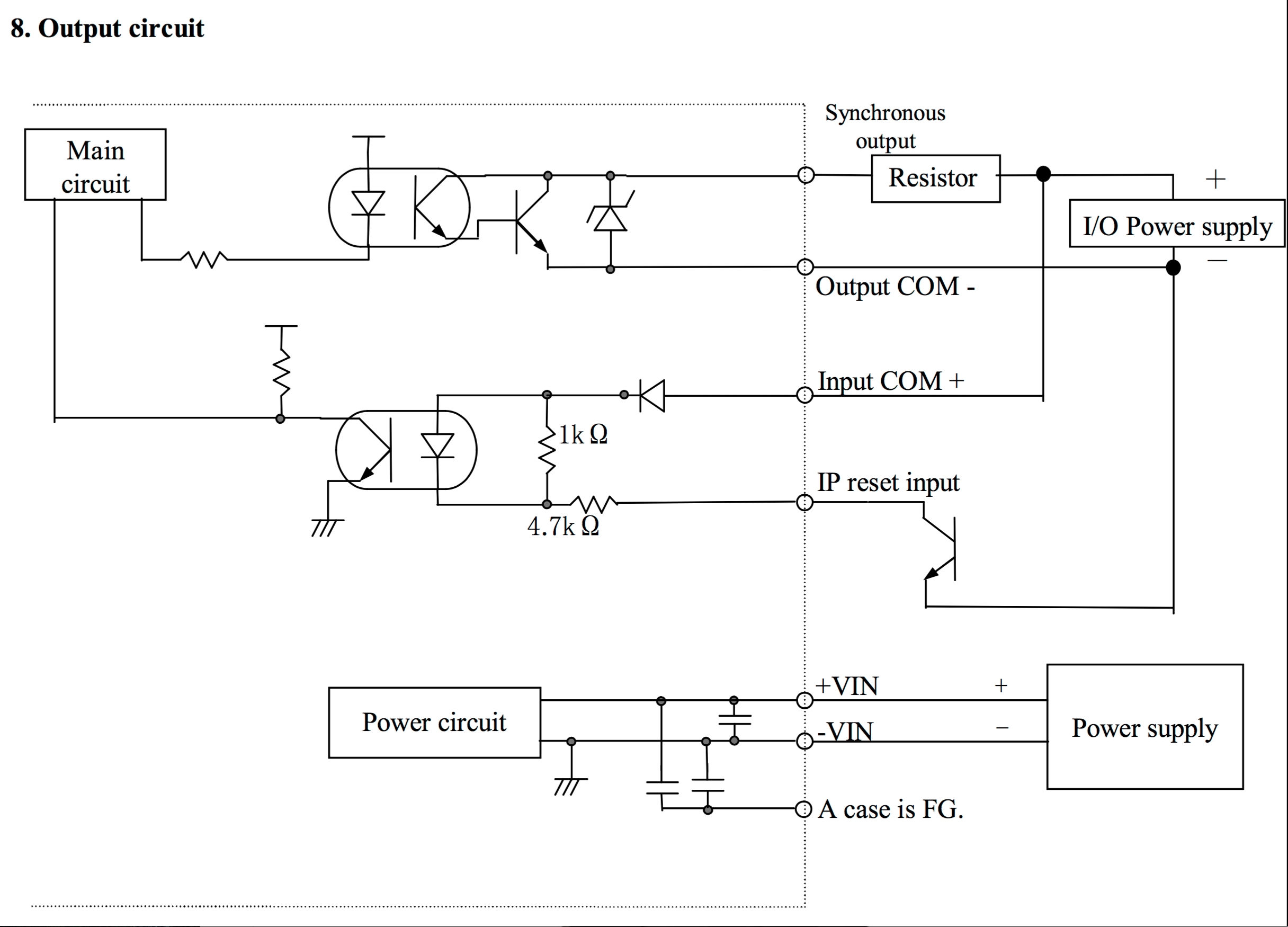

This procedure assumes that the output circuit from Section 8 is in place or has already been implemented:

In the event that you have not implemented the output circuit from Section 8, make sure that you have the Input COM+ (Red) connected to the I/O Power supply (you can use the same 12V power supply that already connected to the unit as the I/O Power supply) and the Output COM– (Gray) connected to the ground of the I/O Power supply as shown. You do not need a transistor at the IP Reset Input. A physical contact of the IP Reset Input to the Output COM- is equivalent to the ON state of this transistor.

So now, with the COM+ input tied high to the +12V output of the power supply, you should be able to reset the IP address of the unit by connecting the IP_RESET line to the COM- signal for ~2s (then releasing them) per Section 10.

Thanks again for choosing Hokuyo and Acroname!

Add New Comment