Multi-hosting on an Industrial USB Hub

In modern manufacturing environments, devices often rely on local USB storage for configuration and firmware updates, data logging, and backup. It is often necessary to update or process this data by connecting the drives to another host, usually by manually unplugging the drives. This takes operator time and, worse, every time they plug or unplug a drive or drag a file to a folder presents an opportunity for error. This application brief presents how Acroname Industrial USB hubs like the USBHub3c and USBHUb3+ can automate host switching and management of multiple drives to keep your workflow error-free.

Figure 1: USBHub3c and USBHub3+

Efficient Firmware Management in End-of-Line Testing

In End-of-Line (EOL) functional testing, products are provisioned with test firmware and software before receiving their final versions. In production lines with multiple product variants, the process becomes more complex as each product may require unique firmware and OS images, requiring frequent intervention.

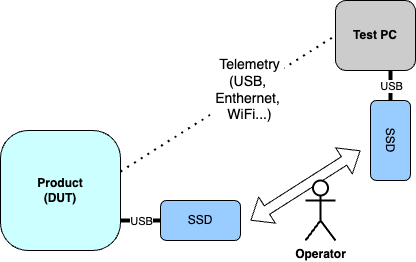

A typical (and time-consuming) manual update process might look like this (Figure 2):

Figure 2: Manual SSD image updating

- Connect an external SSD to the Test PC and copy over the new firmware and OS image.

- Connect the SSD to the product.

- Boot the product module from the SSD to install the firmware and OS.

USB Host switching

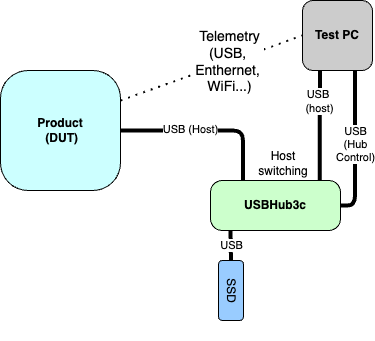

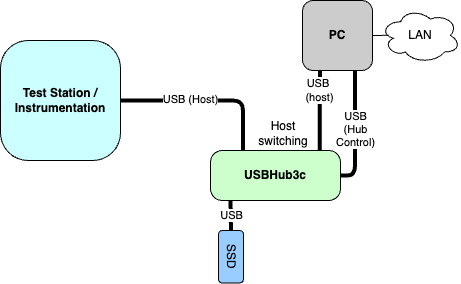

The USBHub3c hub supports USB host switching. With host switching, the hub can assign a host-capable device on any port to become the upstream host and access all connected peripherals. Switching can occur automatically by port priority, or it can be controlled via the hub’s dedicated Control Port.

In this example, a script on the Test PC directs the hub (via API) to select the product as the USB host, allowing it to boot from the SSD. When the production line switches over to provisioning a new product version, the Test PC directs the USBHub3c to select the Test PC as the new USB host. The PC then mounts the SSD and copies over the new image (Figure 3).

Figure 3: Automatic Host Switching

Reducing Changeover Times with Multiple SSDs

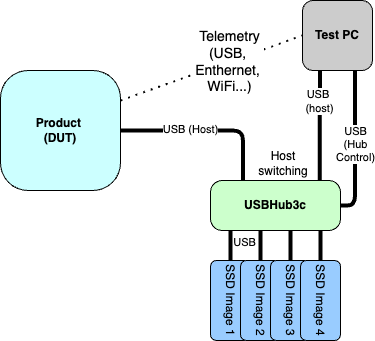

Changeover times can be further minimized by selecting among multiple dedicated SSD images, each supporting a different product configuration. USBHub3c can enable and disable individual ports, so the product will only detect the enabled SSD.

In the configuration shown in Figure 4, a single USBHub3c can support up to four SSDs while maintaining dual-host switching. More SSDs can be easily added by cascading additional Acroname hubs.

Figure 4: Selecting from Multiple SSDs

Updating Test Station Configuration, Data Logging, and Backup

Manufacturing test stations and instruments often log data to local storage that is not network accessible. It is useful to periodically pull test data for QC tracking, archiving, and analysis, or to upload new configuration files. This process is usually performed by an moving a USB drive between the test station and a PC.

Through host switching, a central control system can automatically load updates to local USB storage, while machines can access these files directly when needed. The same system can periodically retrieve log data for timely QC tracking and data analysis (Figure 5).

Figure 5: Host switching for test stations

Boost Efficiency and Minimize Errors with Acroname USB Hubs

Acroname’s USBHub3c industrial USB hub’s host-switching and per-port control can provide significant operational benefits in manufacturing environments. By automating device provisioning and firmware updates, managing multiple storage devices, and enabling seamless data logging and retrieval, Acroname hubs can decrease cycle times and reduce human error, making them a great choice for production environments.

Add New Comment